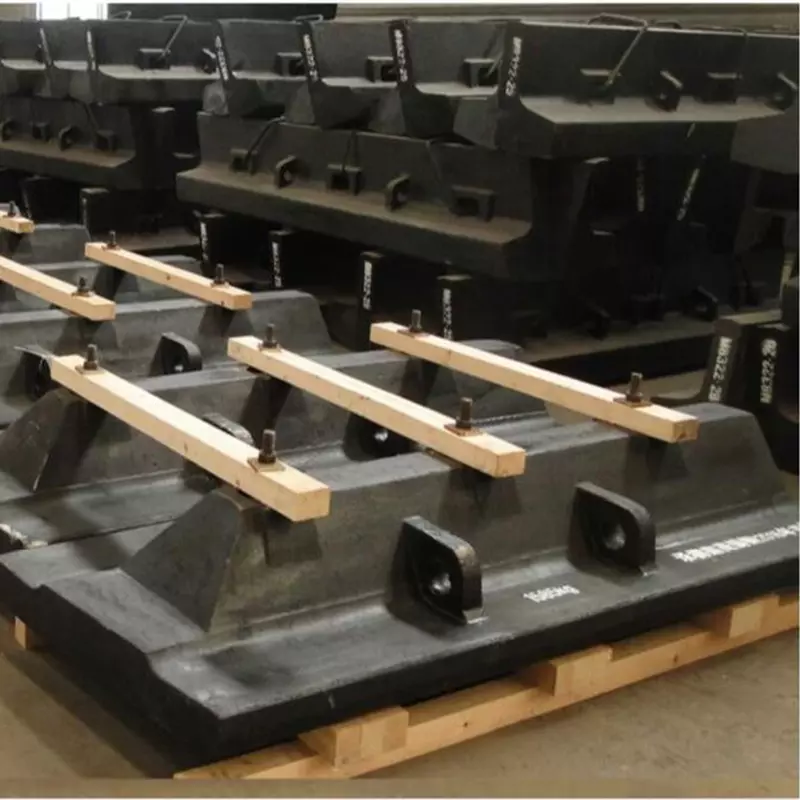

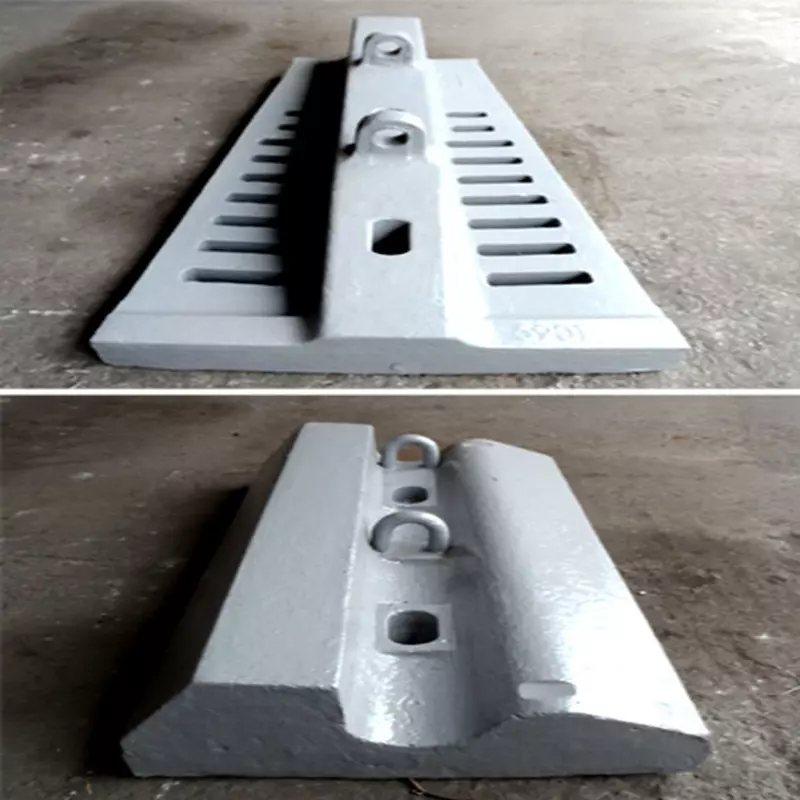

When it comes to mill liners, MGS Casting is a Chinese-leading manufacturer of mill liners and trommels that improve grinding efficiency, reduce downtime, and lead to increased profitability, which specializes in the design, manufacture and after-sales service and support and is a proven provider of total mill lining solutions across the globe.

Mill liners developed by MGS Casting include Ball Mill Liners, SAG Mill Liners, AG Mill Liners, as well as Scrubber Liners. Focusing on the good fitment of liners, in which MGS Casting are experts, results in reduced installation downtime which, in turn, facilitates increased production.

Application Areas

- Autogenous mills

- Semi-autogenous mills

- Ball mills

- Rod mills (metallic)

- Pebble mills

- Batch mills

- Continuous mills

- Scrubbers and washing drums