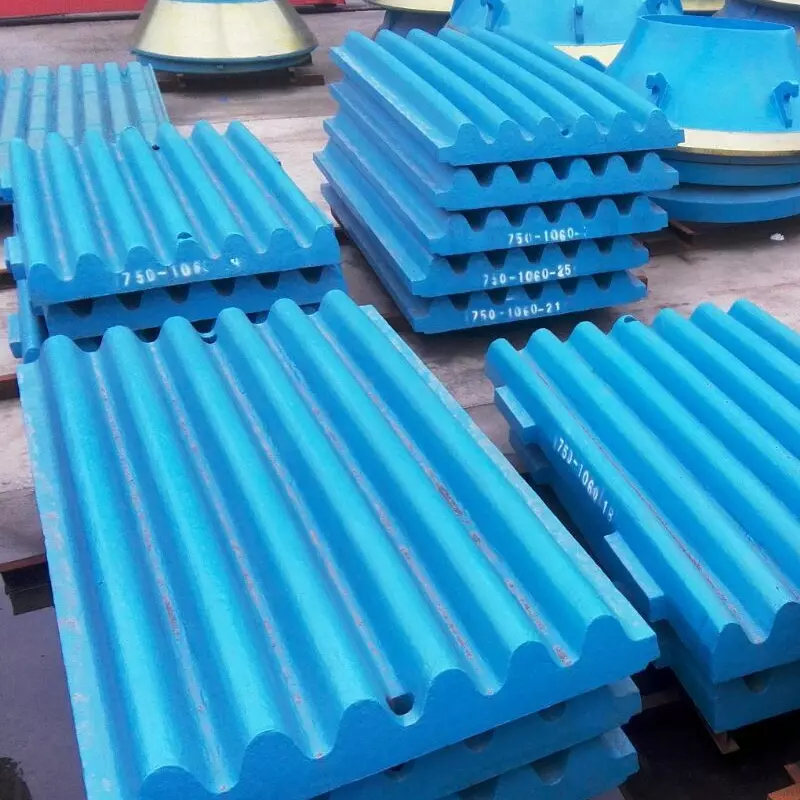

MGS Casting premium manganese steel and alloy crusher liners are independently proven in mining and aggregate production to achieve, and we are one of the largest crusher wear parts supplier in China.

MGS Casting premium manganese steel that has been developed from the original Hadfield’s manganese steel specification, our variation can provide unequaled toughness with excellent resistance to abrasion, which improves as the steelwork hardens in operation.

Available in M14, M18, M21 manganese steel, and TIC Insert wear parts, we have a cost-effective solution to your specific requirements.

Our product engineers are problem-solving specialists, planning crushing surfaces to handle oversized material, split slabby material, and cut back recirculation. Our alloys are tailored to fulfill the extent of impact and abrasion your crushers encounter, leading to higher overall plant performance. For gyratory wear parts, cone crusher wear parts, jaw crusher wear parts, hammer mill wear parts, impact crusher wear parts, and roll crusher wear parts, call MGS Casting.