At the forefront of engineering innovation for two decades, MGS Casting was the first sucessed company to offer titanium carbide (TiC) wear parts in China and has recently added ceramic reinforced alloy (CRA) and tungsten carbide (WC) options for a number of parts. MGS Casting is also well-known for their revolutionary diverter valves allowing rapid in-line maintenance of slurry and cement transportation.

Our commitment to quality and dedication to our customers has resulted in long-lasting relationships with distributors, mines and processing plants worldwide.

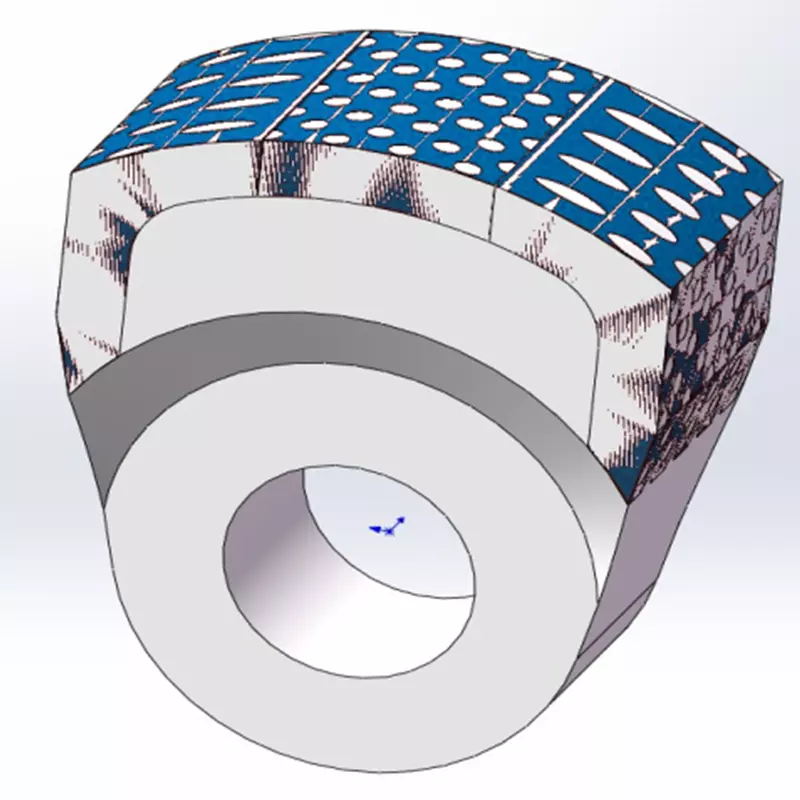

MGS Casting with Titanium Carbide (TiC) inserts deliver outstanding durability. Impactors/Blow Bars, Jaw Crusher Plates, Hammers, and Breaker Blocks are offered in TiC versions. We chose the rhino to symbolize the toughness of the titanium carbide rods that give our wear parts such power.

Titanium Carbide Rods Technical Parameters:

- Hardness (ISO 3878): 82.5±0.5 HRA

- Density : 6.2 ±0.2 g/cm3

- TRS (ISO 3327): 1800-2000 N/mm2

- Average Grain Size: 2.0 ±0.5 μm

- Porosities: A02B00C00

- CHEMICAL: TiC(47%)-Fe(37%)-Ni (2.0%)-Mn (10.0%) Other(4.0%)

Titanium Carbide Rods Types:

Diameter range(mm): (D)8-45mm

Length range(mm): (L)30-100mm

Hot sale sizes(mm): D12x50 D14x60

D12x40 D14X40 D12X60 D12*80

D16X90 D20X40/50/60